EVD evolution, Drive the power easily

The EVD evolution series of controllers for electronic valves

is the latest step in the development of the famous CAREL drivers for superheat

control. Compared to the standard EVD, this instruments adds advanced functions

and a new user interface that makes it even easier to use and configure. The

new TWIN version can independently control two electronic expansion valves, and

represents the ideal solution for two circuit units or different control

function (i.e. superheat and hot gas bypass).

A new graphic display and a simple programming procedure

allow the controller to be started by selecting just 4 parameters:

- refrigerant

used;

- model of valve;

- type of pressure probe;

- application (chiller, display,

cabinet, etc.), selected from the multiple choice menus.

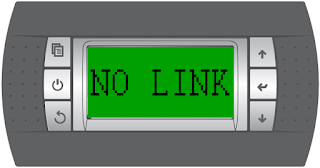

EVD evolution is complete with LEDs for controlling the main

functions, and can house a removal LCD display for the configuration and

monitoring of all the variable.

EVD evolution can be connected to the pCO series controllers

or a PlantVisorPRO supervisor for integrated management of the driver via tLAN,

pLAN or RS485/Modbus; it can also operate independently (stand alone) using a

digital inputs to switch the device on/off. EVD evolution can work as a simple

positioner, using a 4 to 20 mA or 0 to V analogue input signal.

The new EVD evolution series can manage other functions in

addition to superheat control, such as hot gas bypass, evaporator pressure

control (EPR), and transcritical CO2 circuits. Connected to a pCO series

controller EVD Evolution can manage superheat on units fitted with Digital

Scroll compressor, using a specific algorithm patented by CAREL and approved by

Emerson Climate Technology.

Comments

Post a Comment