Cold Rooms for food storage

Food storage uses various

procedures that vary based on duration:

- Refrigeration, if the food must be stored for a short period of time (0…7 °C).

- Freezing, deep freezing and lyophilisation (freeze drying) if it must be stored for long periods.

When deep freezing the product it

must reach a temperature of -18 °C in less than 4 hours while for

regular freezing the product can take more than 4 hours to reach -18 °C.

During lyophilisation the product is dried following a forced evaporation of

the water component of the product.

In the food industry, refrigeration is one of the most delicate and

complex applications because food requires treatment at different temperatures

depending upon the processing phase.

Refrigeration slows the growth of bacteria on food. The technique is

based on the extremely quick and intense action performed by the cold

temperature that allows the organoleptic qualities of the food to be kept

intact, prolonging storage time.

Systems designed and installed on an industrial scale as well as those

for large consumption are based on standard procedures and techniques. The

chiller system is only one part of a more complex system that allows the

evaporator to define the ideal heat exchanger and thus maintain the food.

Cold rooms are a key point in the cold chain.

Proper management has positive impact on both the quality of the

stored product and on the environment in terms of energy savings.

Often the contents of a cold room is of great monetary value and

therefore requires serious and reliable technological solutions.

Depending upon the type of food or system, the cold rooms can be

classified as:

- Normal temperature

(>0 °C,

for storing fruits and vegetables for example)

- Low temperature

(<0 °C,

for storing meat for example)

- Stand-along

(with on-board motocondensing unit)

- With

remote motocondensing unit or monoblock controlled

- Centralised

(without on-board compressor, with remote chiller control unit).

Typically, cold rooms with on-board motocondensing units or monoblock

are located in small sales locations while cold rooms with chillers contro lunits are found in supermarkets and distribution centres.

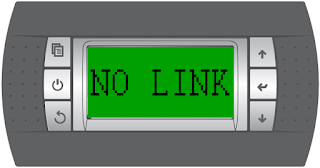

The main elements which must typically be managed by an electronic

controller are:

- Probes for

detecting the room temperature and for defrosting (if included)

- Compressor

- Defrosting

resistors

- Evaporation fans

- Lights

- Door switch

- Alarms

- Condensation fans

CAREL offers its customers various types of electrical panels based on

advanced controllers that are easy to use and extremely flexible.

Hi there! glad to drop by your page and found these very interesting and informative stuff. Thanks for sharing, keep it up!

ReplyDelete- Cold Storage MA

Thank's for your comment!

DeleteI havent any word to appreciate this post.....Really i am impressed from this post....the person who create this post it was a great human..thanks for shared this with us.

ReplyDeleteice cream machines