Catering and hot display cases

Carel offers a series of solutions for hot display cases (bain marie), retarders and blast chillers characterized by a complete line of user terminals. The complete version including a graphic display is capable of meeting the needs of the most discriminating users who are always looking for innovative solutions.

The wide range of products available satisfies all requirements, ensuring a properly stored and high quality product to the final user.

HACCP management is built-in to the latest generation instruments. This ensures temperature control of the food products stored, in compliance with the HACCP system. Parameters are set directly by the instrument.

It is possible to set time and temperature limits required by food storage regulations.The controller automatically monitors the unit, highlighting any critical situations. The standard program allows the complete management of the retarder or blast chiller unit, setting operating cycles, times and variable temperature and humidity set points.

The retarder cabinet also includes an air humidity controller thanks to the wide range of CAREL humiSteam type immersed electrode humidifiers.

The blast chiller controller can manage the regulation temperature and "hot point" temperature separately, deciding which size to display and which to use to regulate the unit in the various conditions.

Once the blast chiller cycle has begun, the controller implements the best strategy to bring the food product to the desired temperature within the set time limit. This solution ensures the temperature control of the food product stored in compliance with the HACCP system, highlighting any critical situations regarding temperature limits and time limits.

Parameters can be programmed directly on the instrument or through the supervisor system, if present.

Solutions for controlling hot display cases and for refrigeration

Temperature controls for "bain marie" applications are typically used in catering and display case applications.

It allows the level of water inside the tank to be controlled via digital input. The logic manages the activation of a solenoid valve for replenishment. Natural evaporation due to near-boiling temperatures leads to the reduction of the level over time.

The controller inside the electrical panel also controls an electrical resistor needed to heat the tank.

The electrical panel is made of the following:

- plastic case;

- circuit board;

- level relay;

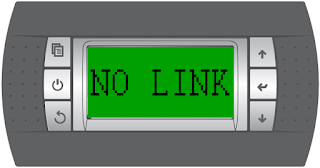

- user terminal;

- electromagnetic power switch;

- support terminal board.

Comments

Post a Comment