The Chiller Control Units

The chiller

control unit is the most important and complex electromechanical organ in the

chiller system. It generates the cold temperatures for all of the connected

chiller utilities and processing rooms.

The CAREL

retail system was designed to meet all the builder’s needs and to provide the

OEM and installers with the best response to their design efforts and to maximize results.

From simple

hermetic compressors in limited numbers or in large racks, to semi-hermetic and

hermetic ones that can be partialised or controlled in frequency.

In terms of

energy savings, the chiller control unit allows wide maneuvering margins with

its considerable installed power. All of our solutions were designed with the

utmost attention to this aspect.

The use of

E2V electronic expansion valves along with the power of the electronic controls

allow the energy balance to be maximized.

Carel offers

two platforms for managing chiller control units: µRack and pRack.

The µRack series offers a series of compact parametric controllers, at a low

cost and particularly easy to use and install on small systems with the

following features:

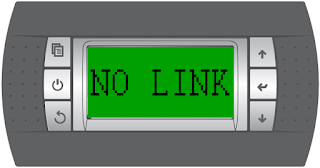

- High efficiency display for monitoring variables;

- Clear and highly visible icons for operating conditions and any anomalies;

- A PWM output for modulating condensation fan control through a speed regulator.

- Operation with floating condensation pressure for increasing the efficiency and yield of the compressor unit.

- Three levels of access for viewing and programming the parameters: (user, installer, builder), with the possibility of reassigning the parameters among various levels.

pRack is the

ideal solution to meet the many needs of the market for control and management

of more complex and advanced centralized chiller control units (i.e. CO2

refrigerant):

- High number of inputs and outputs per control needed;

- Innovative management algorithms for energy savings;

- A unique regulation software in six languages, compatible with various hardware sizes and with a wide range of integration/supervision possibilities;

- Possibility of separating the compressor controller with a unique user interface and local network connection between controllers.

- Drastic reduction in electrical connection costs for remote fans.

- Regulation of modulating capacity through dedicated outputs for compressor side inverter and/or inverter/cut-off controls for condensation fans.

- Operation with floating condensation pressure for increase the efficiency and yield of the compressor unit.

Comments

Post a Comment